By Jeff K.

The IBM360-30 uses Printed Card Capacitor storage for microcode.

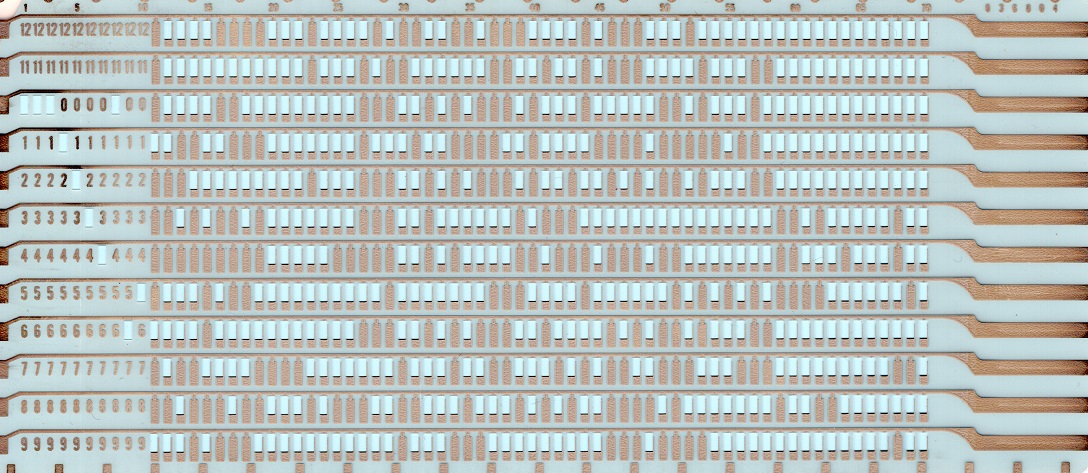

The cards were created by printing Silver ink on Mylar:

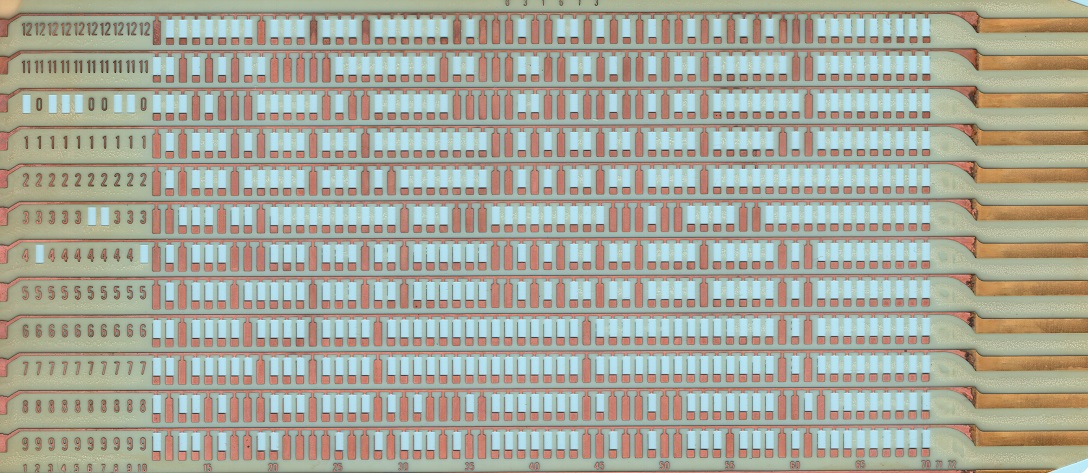

Or etched copper:

304 cards make up the microcode. I scanned them all.

My procedure was to remove one card, clean it, scan it, and then replace it before removing the next card. My original thought was to clean the cards thoroughly using water, possibly with soap, as the machine was stored in a damp location. However, the cards turned out to be quite clean, and only required wiping.

Scans were captured at 24-bit color, 600-bpi resolution. The captured area was 3.15″ x 7.25″, and saved as .BMP files (24MByte). I used different color backgrounds, and chose the sky-blue background as providing the best contrast for my eyes. Processing of the images used the Blue channel. Determining a threshold of hole/not hole was tricky, as there were two types of card, and each card had two areas to decode: the first 10 columns as card ID, and columns 11 through 70 for microcode data. Registration of the scans was quite consistent for row alignment, but column alignment was variable. Only one card needed adjustment vertically, but all card images were trimmed to align the first column. Data was decoded from the card images and stored in a card archive.